Warwick Brickworks

(An Example of How a Brickworks Operates)

The Schnitzerling Family

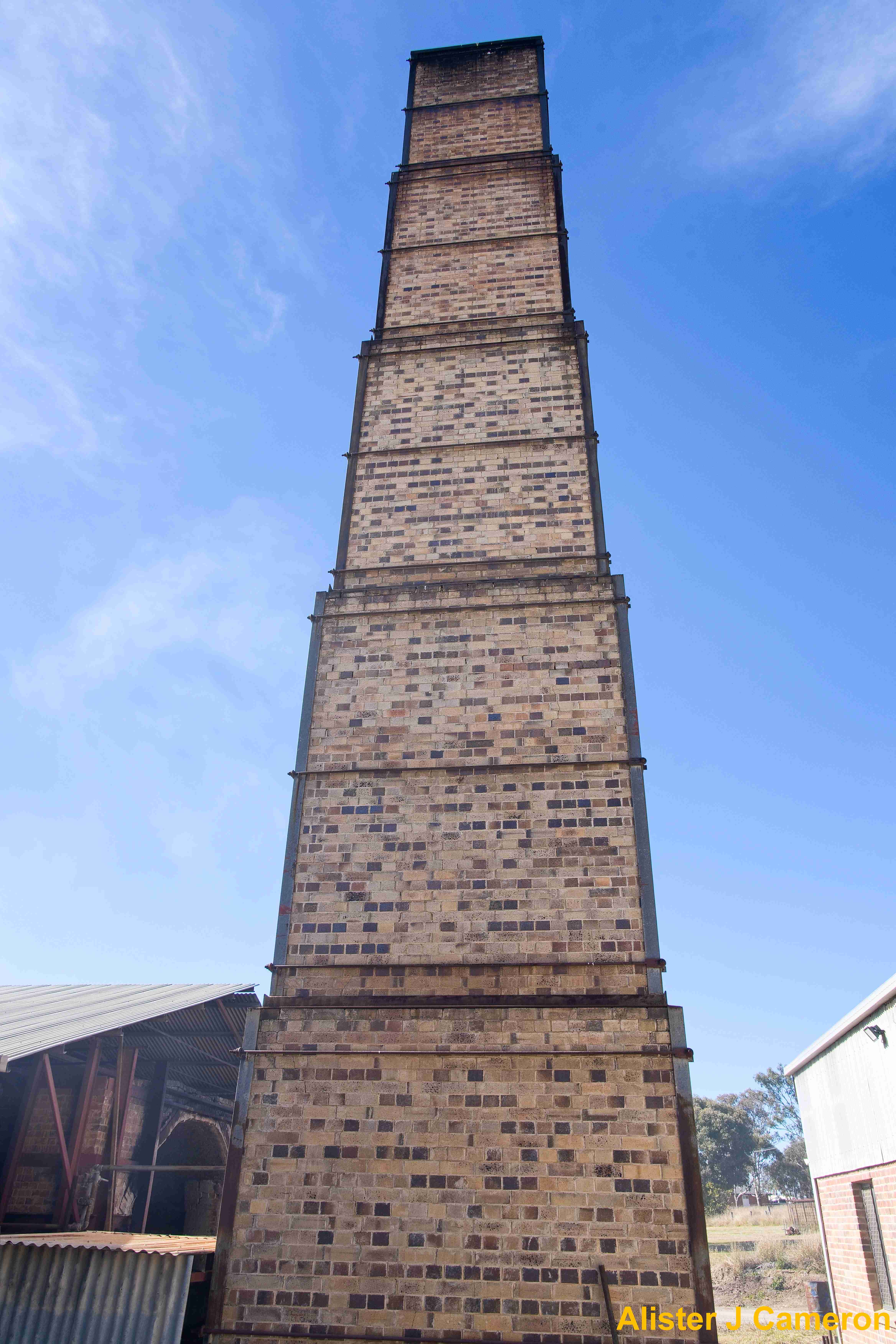

Views of the Brickworks

The Steps in Brick-making Used at the Site

(1) Initial Processing

(2) Grinding

(3) Mixing

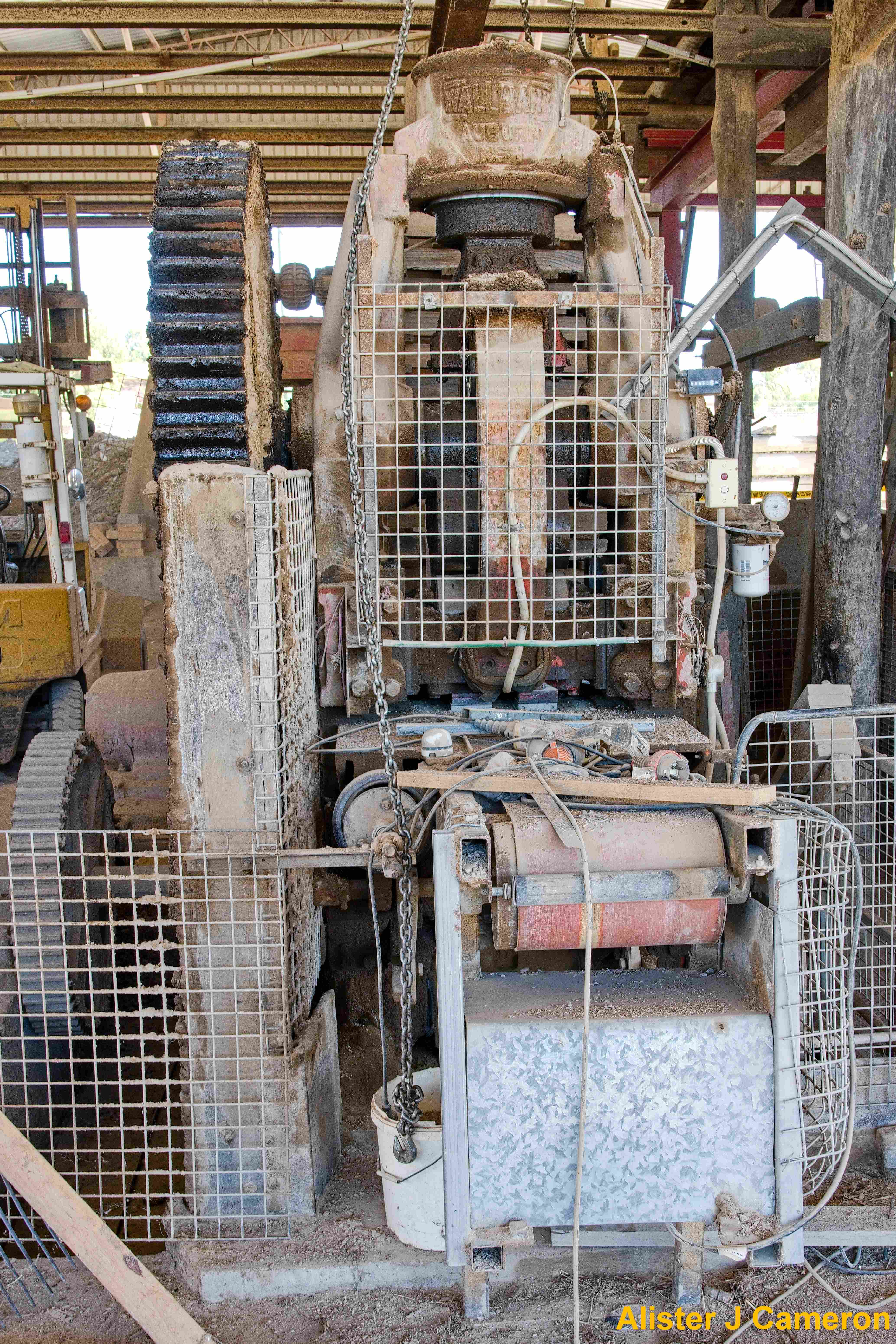

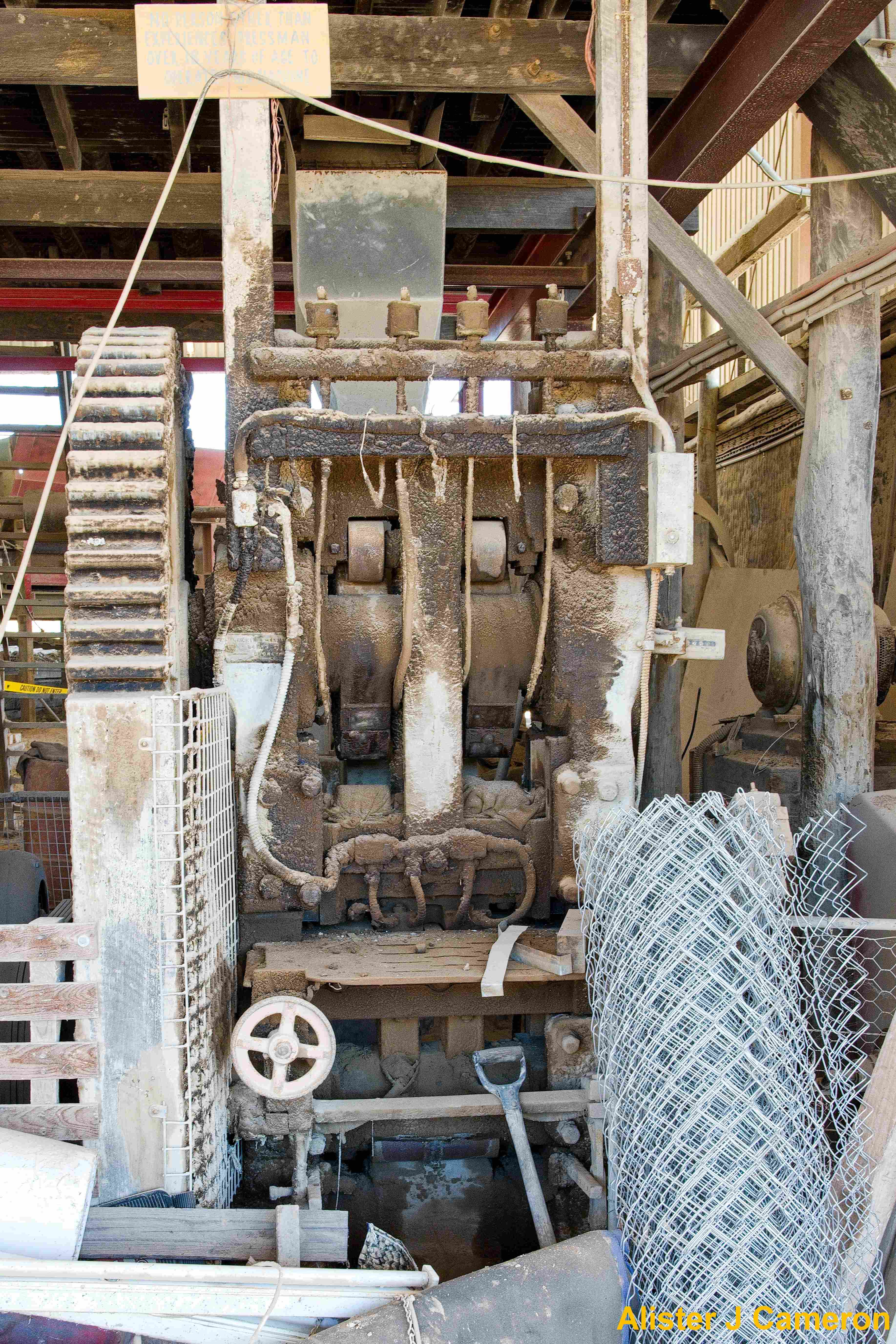

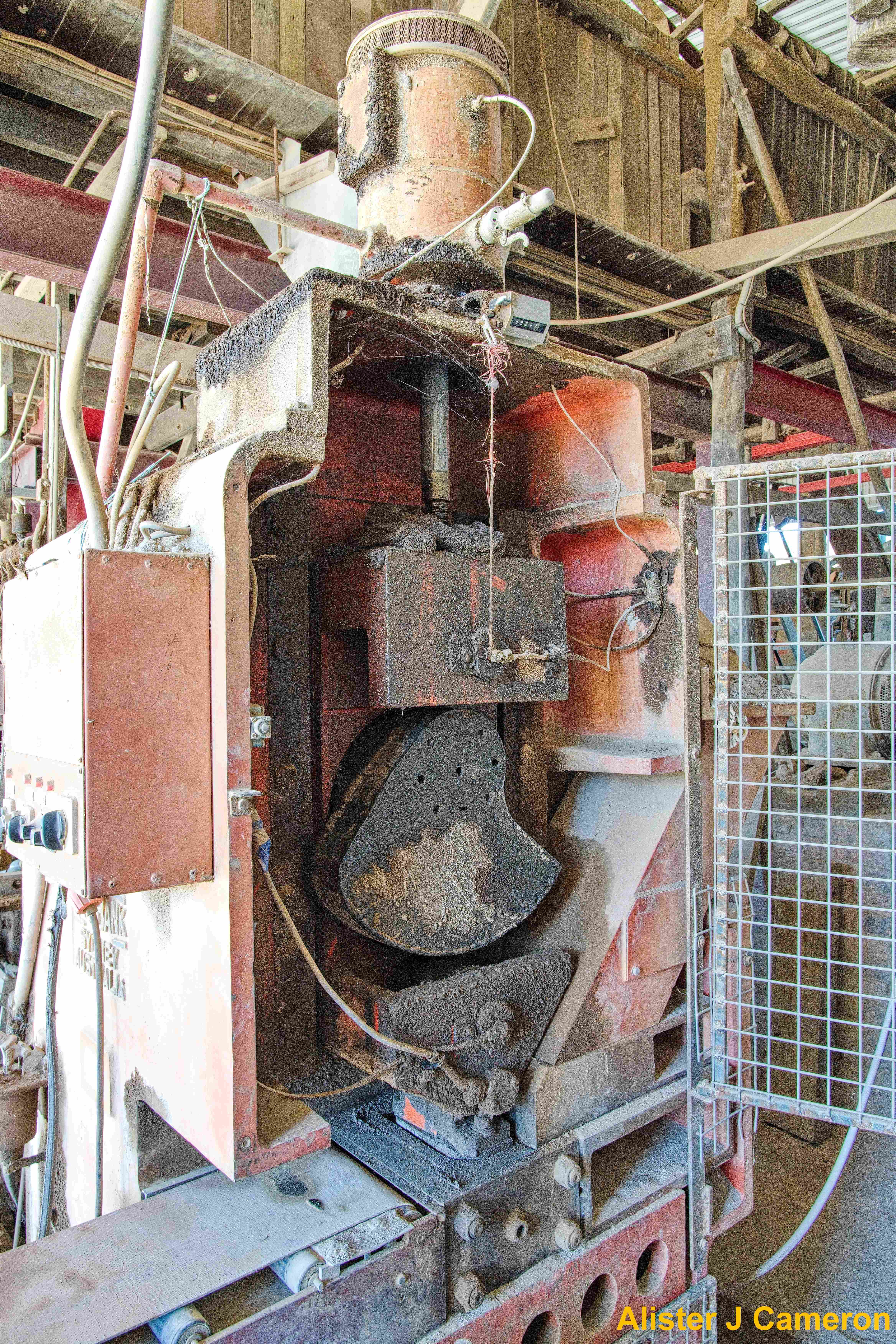

(4) Pressing of the Bricks

(5) Transport to the Kilns

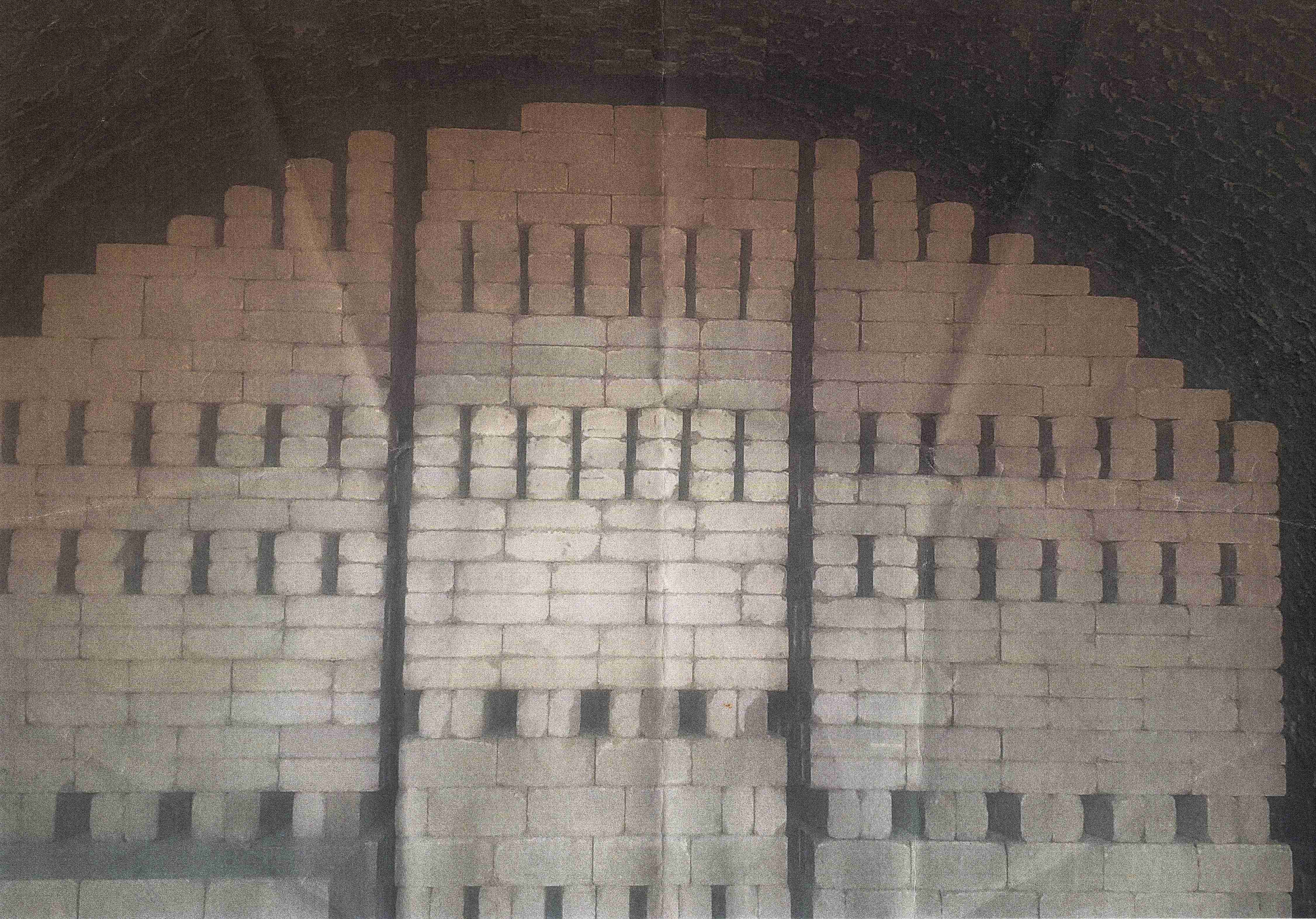

(6a) Firing in the Kilns (Current Kilns)

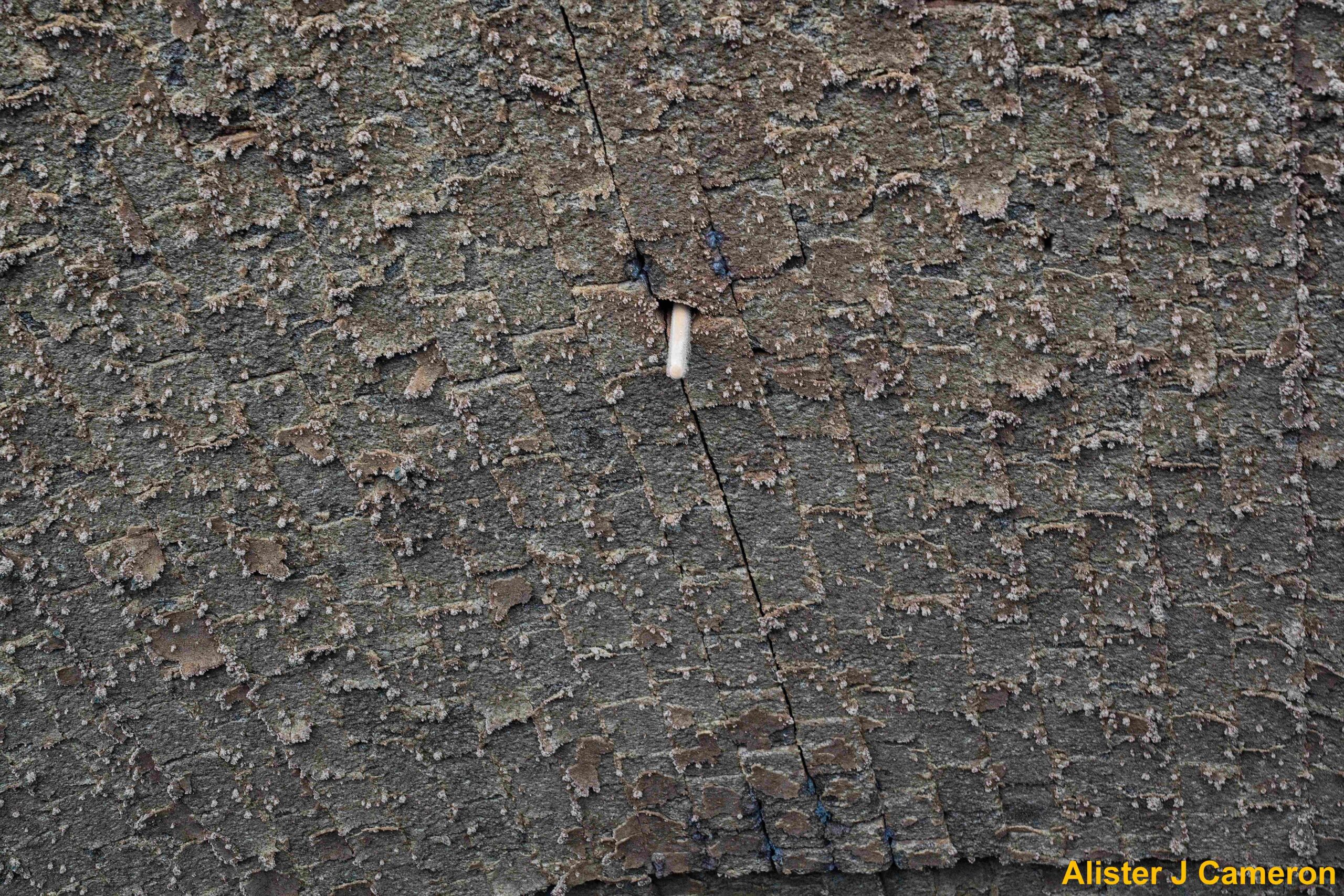

(6b) Firing in the Kilns (Chimney)

(6c) Firing in the Kilns (Former Kilns)

(7) Post-Processing (Tumbling)

(8) Bricks Ready for Sale

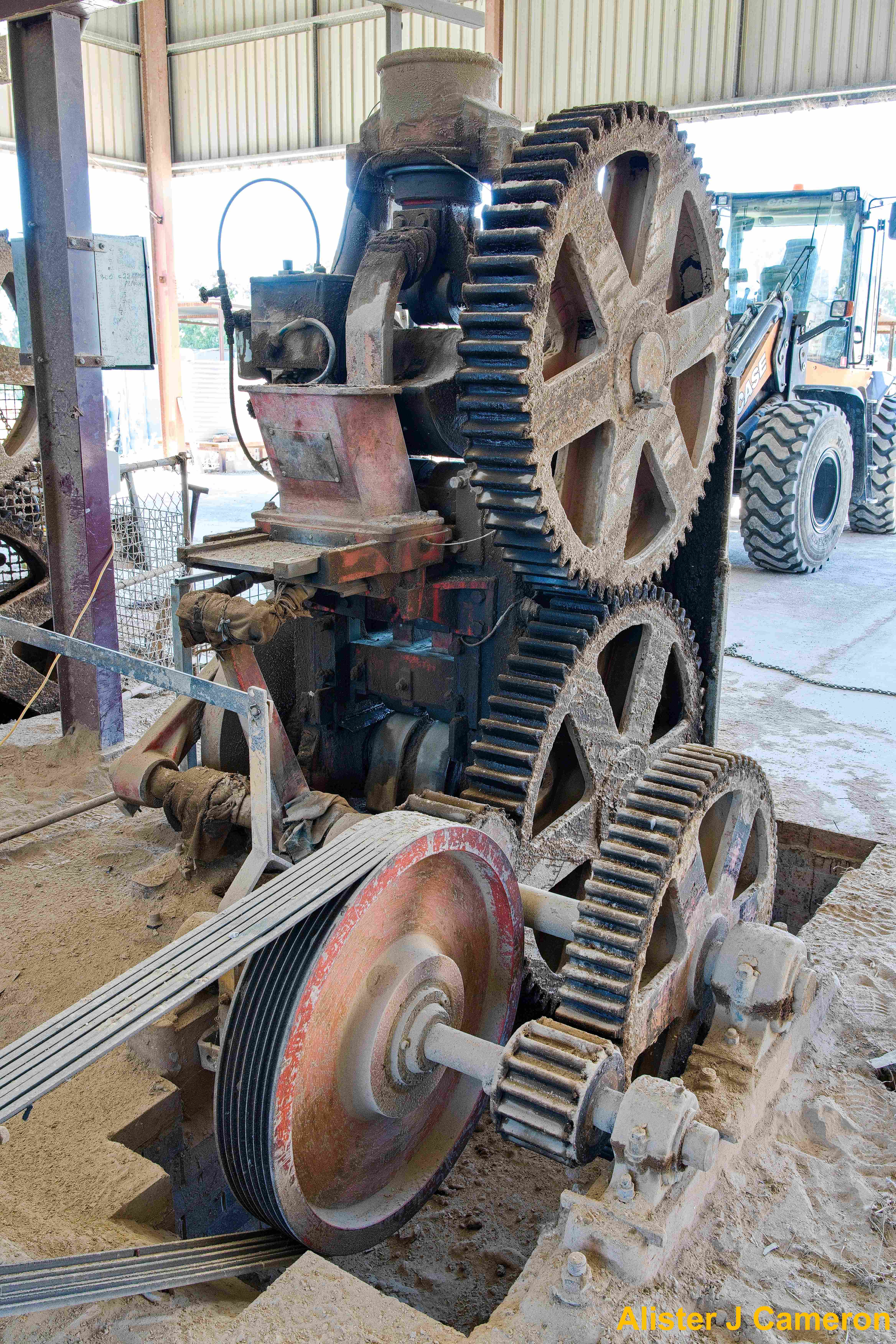

Ancient Machinery on the Site

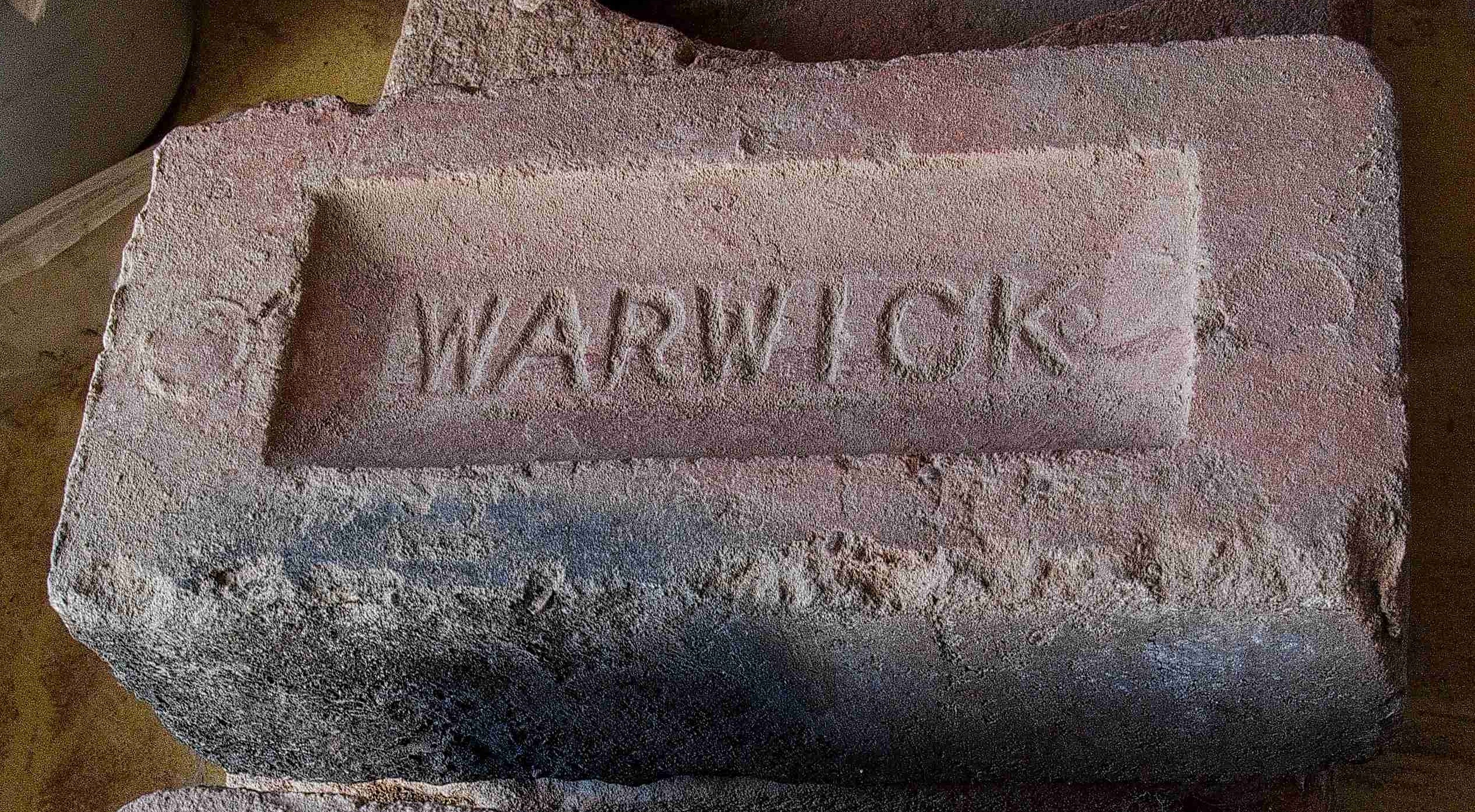

Some of the Older Bricks Made by the Family

More Recent Bricks Up Until Recently on Offer

Description: Light Orange-Brown Brick. Tiny grains, but smooth surface.

Condition: Intact.

Type: Solid, House Brick.

Frog: Narrow, deep, angular frog.

Inscription: None.

Origin: Warwick Brickworks.

Current Location: My Collection.

Description: Light-Coloured, Tumbled “Sandstock” Brick. Totally covered with tiny white and reddish-brown specs. Black impurities. Edges crumbled.

Condition: Intact.

Type: Solid House Brick.

Frog: Narrow, deep, angular frog.

Inscription: None.

Origin: Warwick Brickworks.

Current Location: My Collection.

Description: Dark-Coloured, Narrow, Sample Brick.

Dimensions: 22.5 cm x 7.5 cm x 7.5 cm

Condition: Intact

Type: Sample House Brick

Frog: Deep, narrow, angular frog.

Inscription: None.

Origin: Warwick Brickworks.

Current Location: My Collection.

Description: Light-Brown Paver.

Condition: Intact.

Type: Paver.

Frog: None.

Inscription: None.

Origin: Warwick Brickworks.

Current Location: My Collection

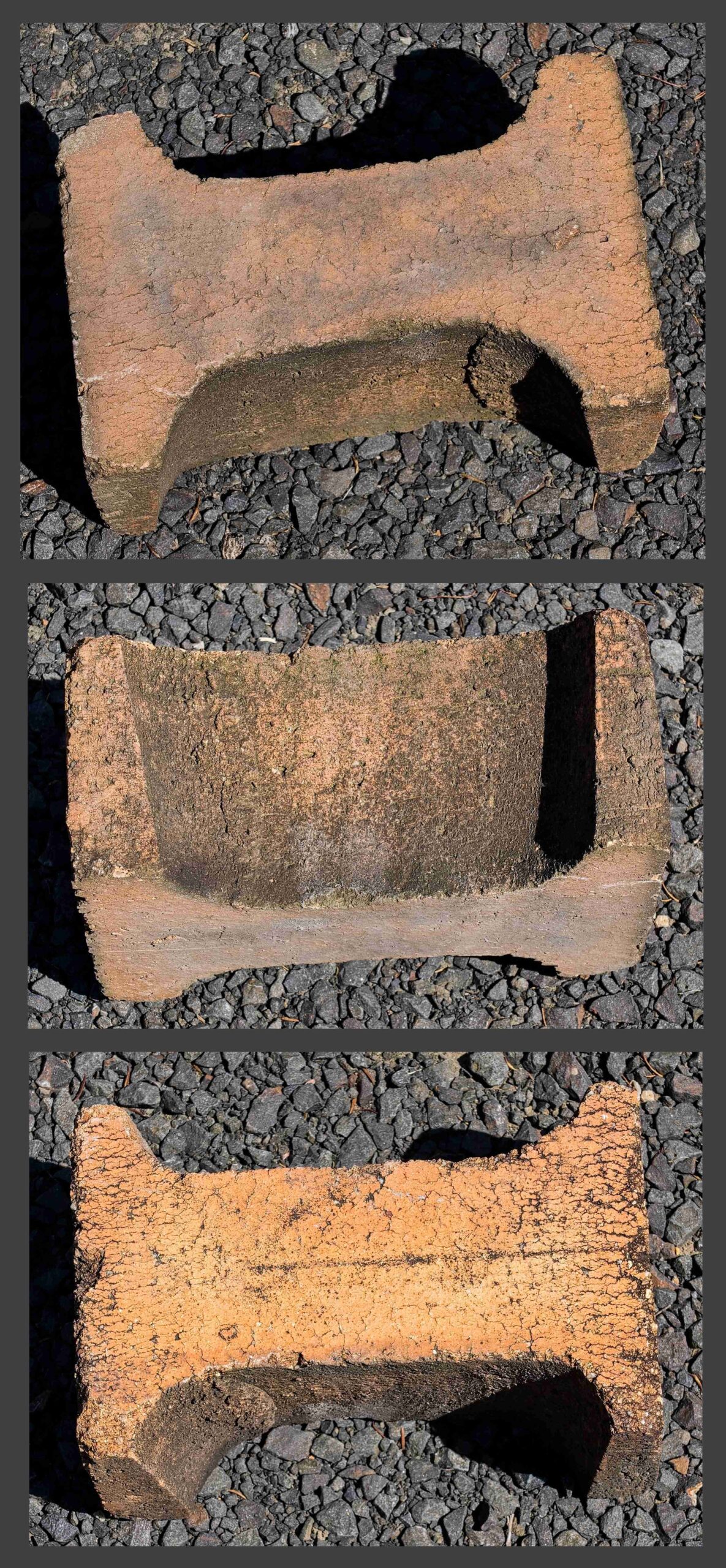

Description: Light-Brown Arch Brick. Many small impurities. Slight wire mark. Narrow edge slightly glazed. Darkened one side.

Dimensions: 22.5 cm x 9.0-10. cm x 7.0 cm

Condition: Fully intact.

Type: Arch Brick (for Kiln).

Frog: None.

Inscription: None.

Origin: Warwick Brickworks.

Current Location: My Collection.

Description: Light-Brown Arch Brick.

Dimensions: 23.0 cm x 11.3 cm x 7.0-7.5 cm.

Condition: Fully intact.

Type: Arch Brick (for Kiln).

Frog: None.

Inscription: None.

Origin: Warwick Brickworks.

Current Location: My Collection.