Claypave Brickworks

A special thanks to Con Bassili and the people of Queensland Property Group for generously allowing me extensive access to the site and the opportunity to collect a number of artefacts for future posterity.

How Claypave Described Themselves in Happier Times

Claypave is an Australian company privately owned and operated by a small group of “hands on” people.

We specialise in the manufacture of clay pavers, and are the market leaders in paver quality, service and innovation. Our extensive product range includes Domestic and Commercial Pavers, Large Format Pavers, Refractory Bricks and Accessories.

The original company, Rylance Collieries and Brickworks began operation in the 1880’s with our current refractories plant being built at Dinmore near Ipswich in the 1930’s. The current owners took over manufacturing operations in 1985.

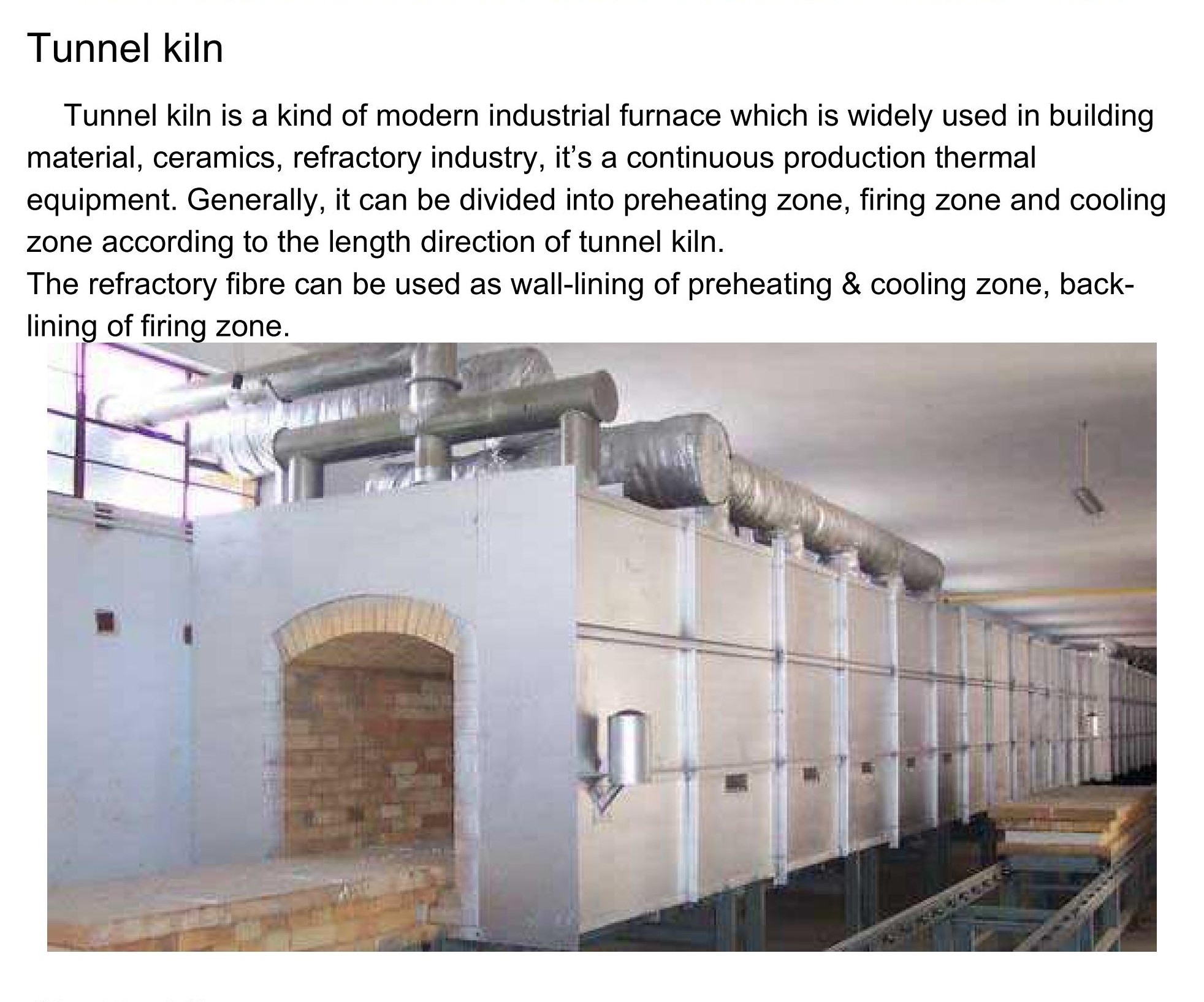

The new company made a strategic decision to focus primarily on the manufacturing of quality pavers. This proved so successful and demand grew so dramatically that we were able to build the first dedicated, state of the art paving factory in Australia in 1988. Demand continued to grow so dramatically that it was decided to again increase our production capacity. The opening of our second tunnel kiln and dryer in 1994 effectively doubled our production capacity enabling us to cope with the increased demands for our products.

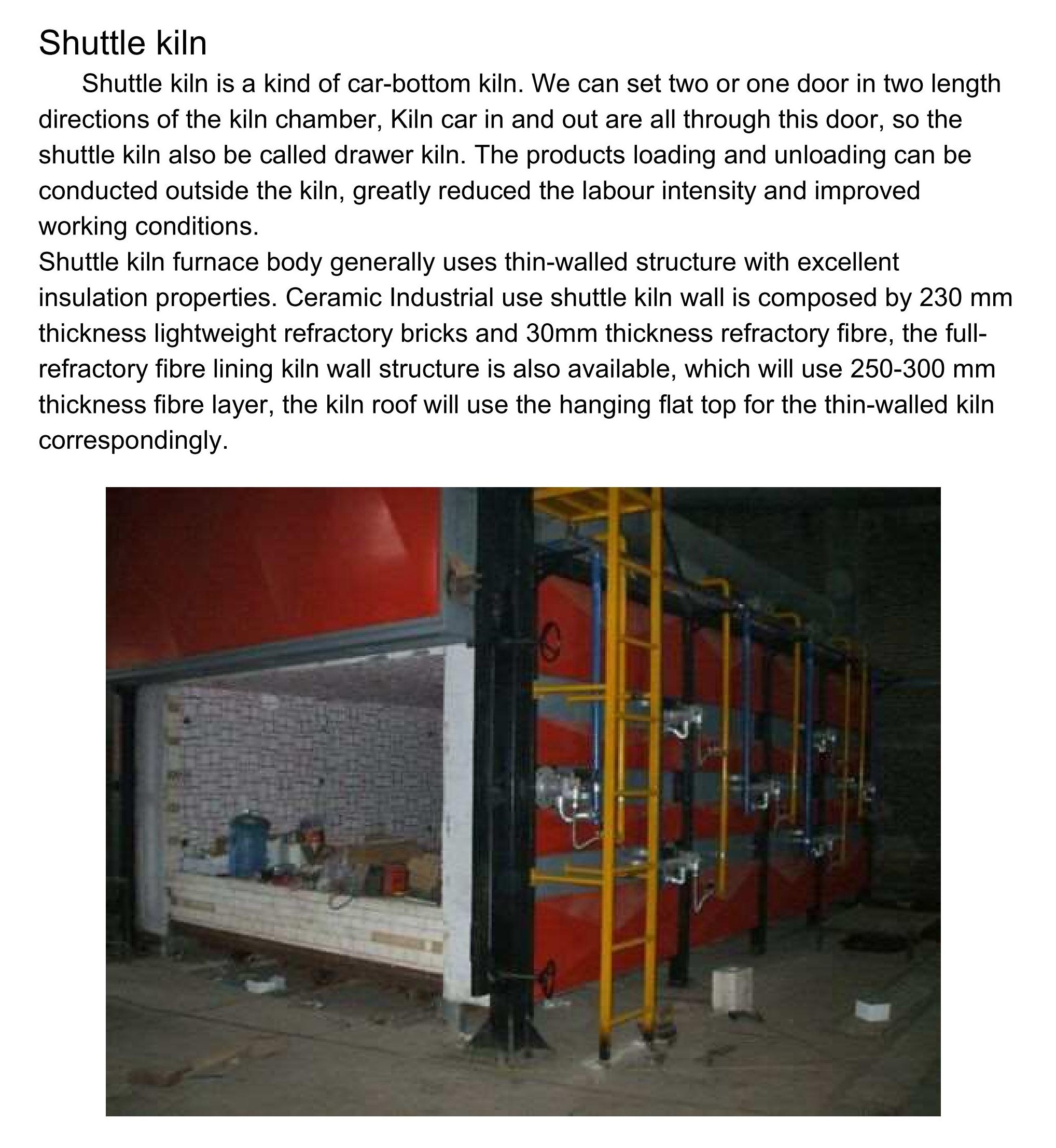

Changes in consumer trends to larger format pavers has meant that Claypave further expanded its production capabillites to enable the production of 300 x 300mm pavers. To get into this market Claypave’s shuttle kiln and dryer system was completed February 2001. The kiln was able to burn between 500m2 and 600m2 of Megapave at a time and able to cycle 3 burns per week.

Source: https://www.datanyze.com/

.

Website: http://www.claypave.com.au

Industry: Wholesale Building Materials

Company size: 51-200 employees

Headquarters: New Chum, Queensland

Source: Linkedin.

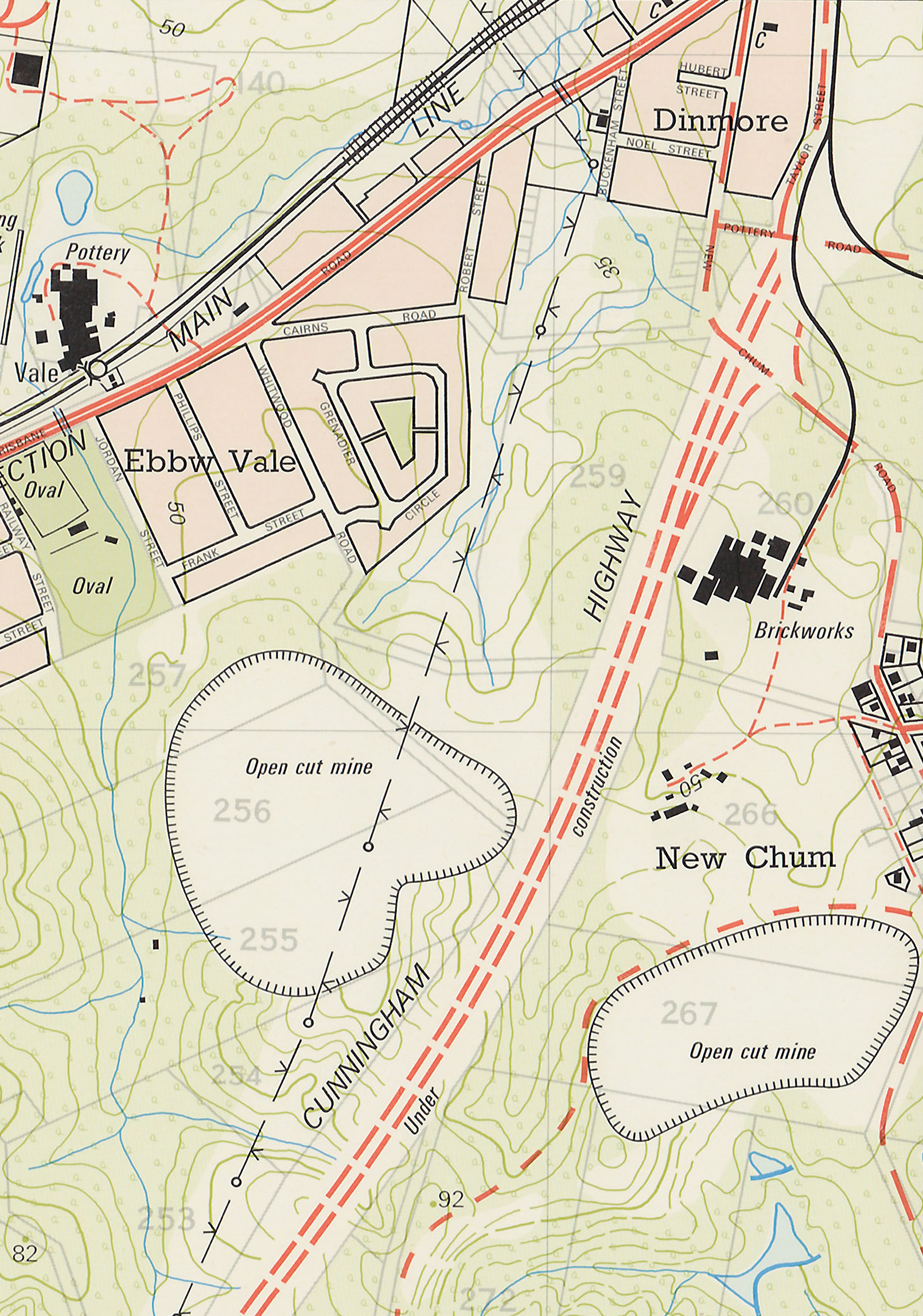

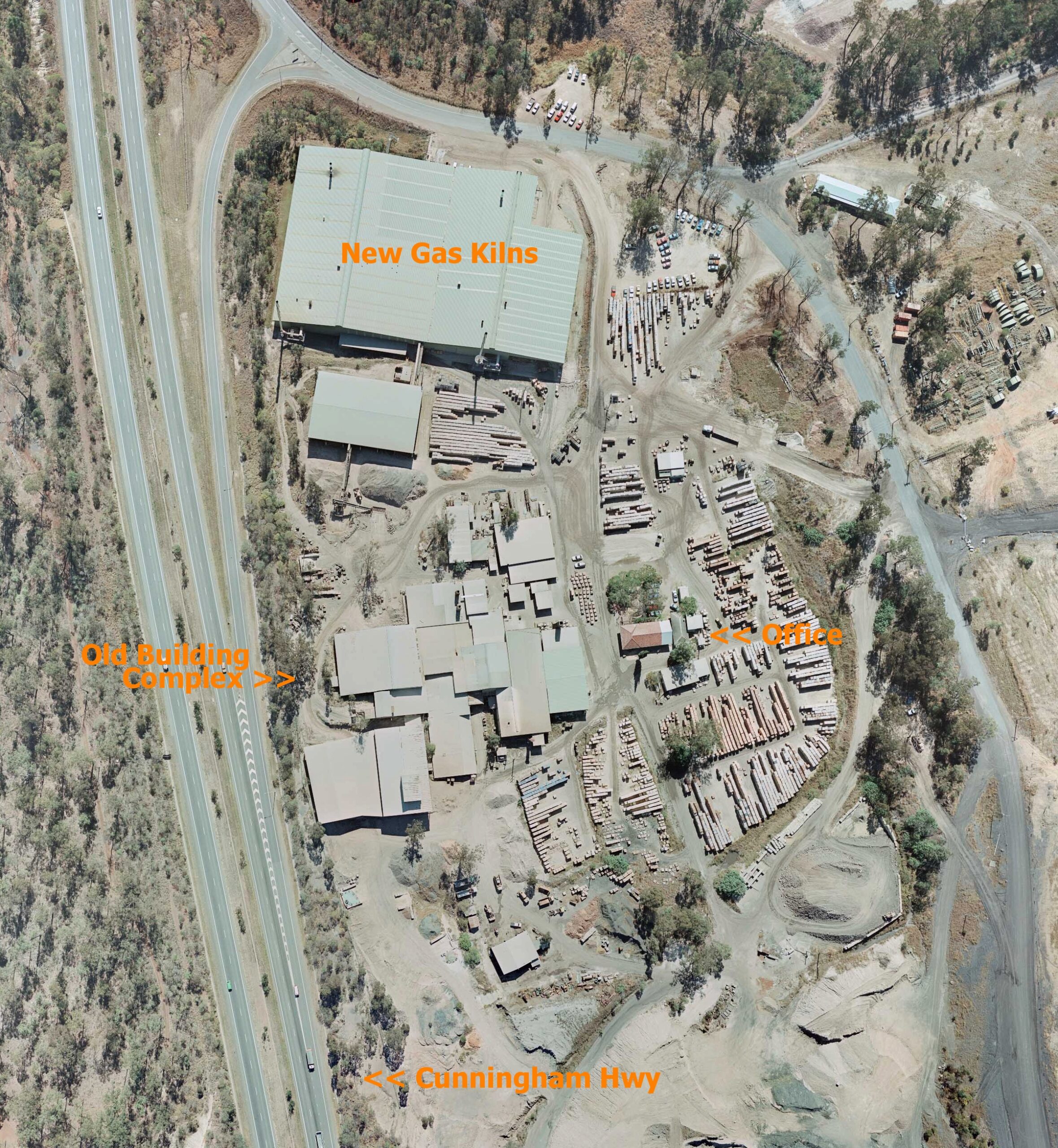

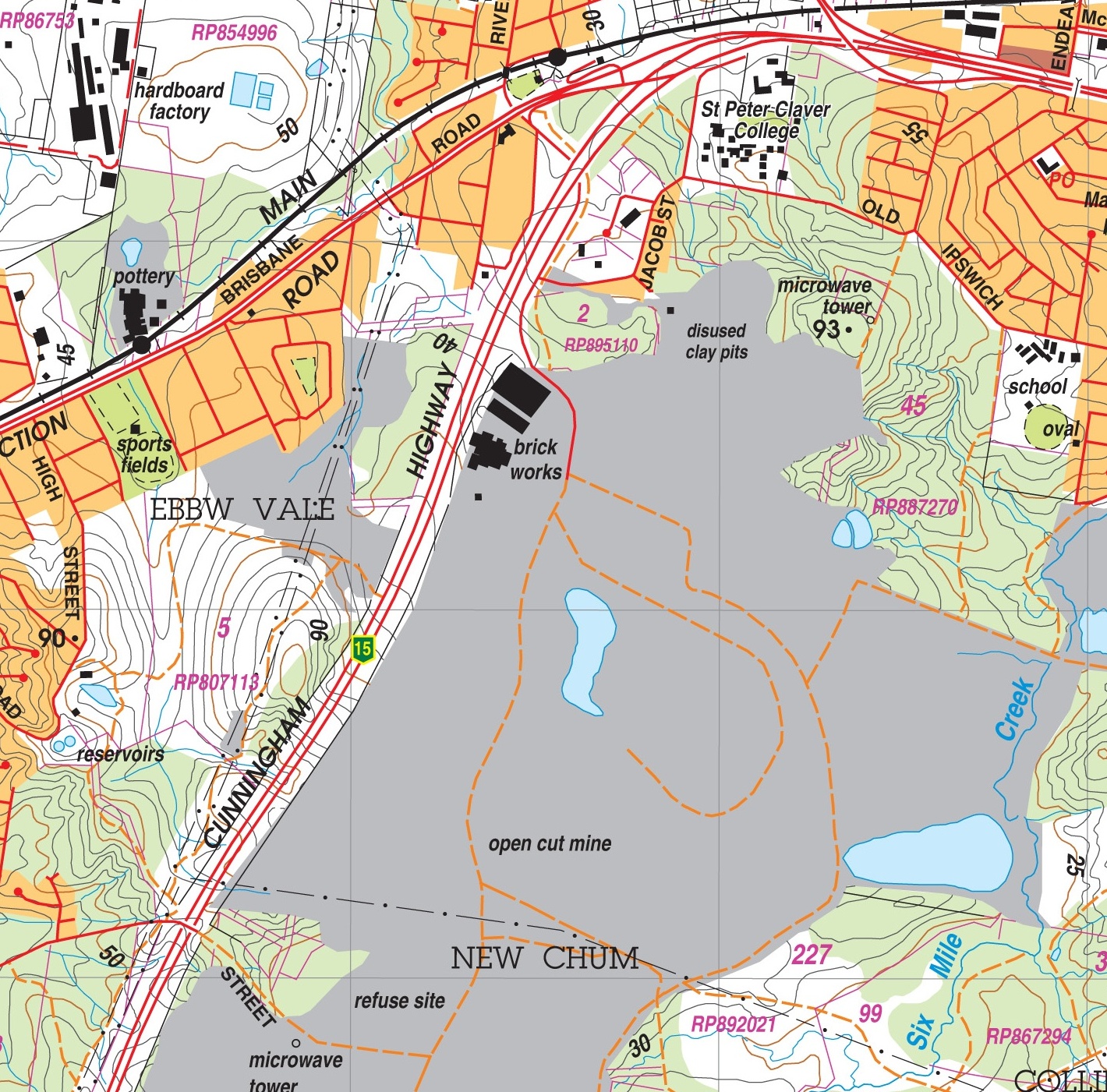

Maps & Aerial Photos

The Site

Inside The Old Building Complex

The Old Kiln

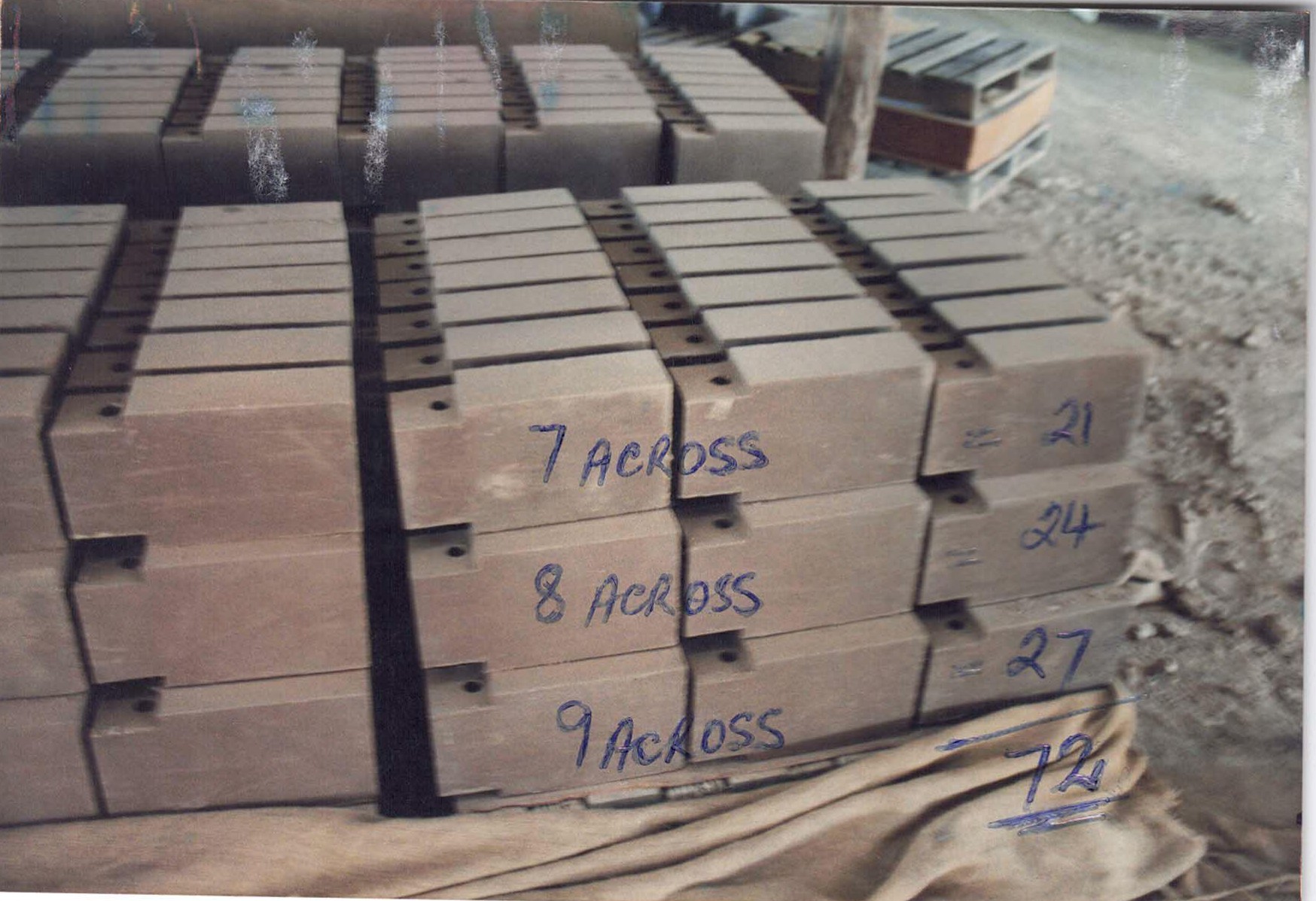

The "New" Kilns